We hope you enjoyed Part 1 of our Chocolate Origin blog series, 'Before It Becomes Chocolate, There's a Tree'. Now we want to take you through the steps to get from the cacao pod to the chocolate we know and love:

Harvesting

A cacao pod will begin to ripen 5-6 months after it flowers.

Image Source: https://cocoanibs.files.wordpress.com

Image Source: https://cocoanibs.files.wordpress.com

Each pod contains beans, the seeds of the fruit that are shaped like a flat almond, surrounded by a sweet pulp. There are roughly 30-50 beans in a typical pod.

Image Source: https://bloguldeciocolata.files.wordpress.com/

Image Source: https://bloguldeciocolata.files.wordpress.com/

These beans are what ultimately get transformed into cocoa powder or chocolate. Once the pods are ripe, they are cut down from the trees, typically with machetes or, for the higher pods, using long poles with a cutting edge. Though pods can be harvested year round there are two major harvest times: the main harvest and the mid-harvest, which falls about six months after the main harvest. Once on the ground, the pods are graded for quality and placed into piles. The pods are then opened with a machete or a wooden club by cracking the pod so that it can be split in half. The beans and pulp are scooped out quickly and either heaped in a pile on mats or banana leaves and covered, or put into a bin or box with a lid.

Image Source: https://onthecocoatrail.files.wordpress.com

Image Source: https://onthecocoatrail.files.wordpress.com

When they are first removed from the pod, the beans have a white, mucus-like coating around each bean. It is sweet and yet tart. It’s a bit like a very sweet lemon and is incredibly refreshing on a hot tropical day.

Fermenting

The beans must be carefully fermented to bring out the very best flavors. Fermentation also removes tannins, which cause the astringent flavor in chocolate and making it more enjoyable for most palates. Fermentation is essential to the development of a high quality cacao bean that will be transformed into gourmet chocolate. Fermentation times from five to seven days are typical. When the fermentation is complete, the cocoa beans must be removed from the boxes or from under the banana leaves and carefully dried.

Drying

Image Source: http://polynelise.com/

Cocoa beans are dried after fermentation in order to reduce the moisture content from about 60% to about 7.5%. Drying must be carried out carefully to ensure that off-flavors are not developed.

Cacao beans are often dried in the sun, which can happen on tarps, mats, or patios. They are continually raked so that they will dry more evenly. The drying process can take up to a week. Artificial drying may be resorted to in countries where there is a lack of pronounced dry periods after harvesting and fermentation, such as Brazil, Ecuador and in South East Asia and sometimes in West Africa. Once dried, cacao beans can be stored for 4-5 years.

Roasting & Winnowing

When the dried cacao beans arrive at the processing plant they are first cleaned to remove any debris. Next, to bring out the chocolate flavor and color, the beans are roasted. The temperature, time and degree of moisture involved in roasting depend on the type of beans used and the sort of chocolate or product required from the process.

Image Source: http://misscheesemonger.com/

When people think about chocolate making, they often overlook one important step—the winnowing process. Each cocoa bean is surrounded by a fibrous husk. When the cocoa pod is on the tree, this husk serves to protect the interior of the bean from animals that may break into the pods to eat the sweet pulp that surrounds each bean. When moist, this husk is soft and pliable, but once dry, the husk forms an almost impenetrable barrier—and one that must be removed in order to make a smooth chocolate at peak flavor. Once roasted, the beans are poured into a winnowing machine, where they're cracked open and separated through a vacuum-powered wind vortex.

Image Source: http://www.formaggiokitchen.com/

Grinding & Conching

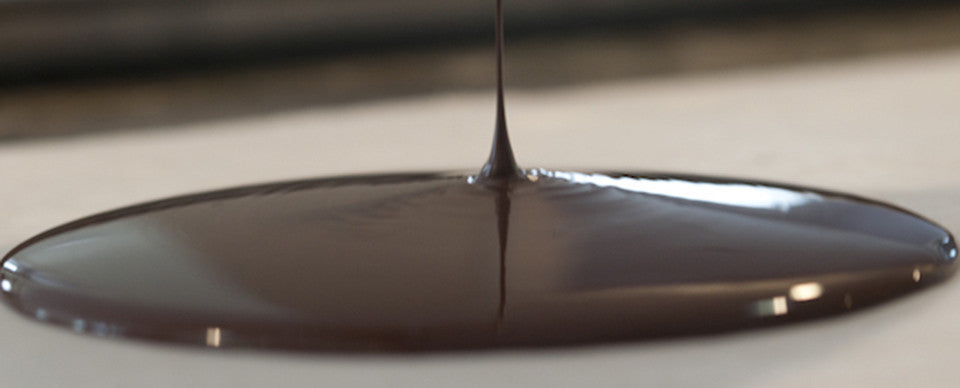

After winnowing, the cocoa nibs are ground with stone rollers until they become a paste known as cocoa mass or cocoa liquor. Despite the name, chocolate liquor has absolutely no alcoholic content.

Image Source: http://www.davidlebovitz.com/

This pure, unrefined form of chocolate contains both cocoa solids (the chocolatey part!) and cocoa butter (the natural fat present in the bean). Cocoa butter can be extracted from the cocoa mass with a hydraulic press. This is useful because most chocolate makers often use extra cocoa butter to give their chocolate a smoother, glossier texture. Some confectionery manufacturers replace this extra cocoa butter with cheaper vegetable fats, and this is something you should look out for on the ingredients and try to avoid. The only fat in real chocolate is cocoa butter.

The cocoa mass is then transferred to a separate machine called a conch, where it is further refined. Many modern artisans combine the grinding and conching into a single process using a machine called a melanger. This is simply a large metal cylinder with two rotating granite wheels that grind and refine the chocolate into very small particles. It’s during this process that sugar, milk powder (for milk chocolate) and other flavourings are added to the chocolate. The conching process can take anything from a few hours to a few days and affects the chemical structure of the chocolate, as well as the particle size. This part of the process has a very big impact on the flavour notes in the finished chocolate, and deciding exactly how long to conch for is part of the chocolate maker’s skill.

Tempering & Molding

Chocolate should have a shiny finish and a good “snap” (when you break a piece!) These characteristics are created by tempering the chocolate. The tempering process is the raising and lowering of the temperature of the chocolate to form the perfect kind of crystals. If you were to let untempered chocolate cool naturally, it would be soft and crumbly and would not melt evenly on the tongue. Tempering can be done by hand, but to make the process more efficient, most chocolate makers use tempering machines that can heat large amounts of chocolate very accurately.

The final step in making a finished chocolate bar is pouring it into a mold. The melted chocolate is simply poured into plastic bar-shaped molds and agitated to remove any air bubbles. Larger chocolate makers will have machines and conveyors that deposit exactly the right amount of chocolate into each mold, but many smaller manufacturers still do this part by hand.

Tasting

Take a chocolate tour around the world with our new single origin solid chocolate bars. We've created a tasting sampler to compare flavors from different chocolate producing countries.

|

Milk Chocolate Single Origin Tasting Bars |

Dark Chocolate Single Origin Tasting Bars |

Sources: Amano Blog, Equal Exchange, International Cocoa Organization, Cocoa Runners